積層製造3D生物陶瓷顱骨鑽孔蓋骨移植替代物

積層製造3D生物陶瓷顱骨鑽孔蓋骨移植替代物

「慢性硬膜下血腫」指在硬腦膜與蛛網膜之間出現出血性血液積聚,是神經外科常見疾病之一,而顱骨鑽孔術是臨床治療此疾病的首選手術方法,臨床上填補鑽孔的材料大致分為鈦金屬、不降解聚合物(PEEK、PMMA)、生物高分子(PCL、PLA等)和生物降解陶瓷等,然而鈦金屬存在影像干擾與不利光波與聲波腦部治療的問題,不降解的聚合物則有發炎與不舒適的風險。可生物降解的PCL、PLA等高分子,雖然有骨整合的能力,惟其骨細胞親和性與骨整合速率較生物陶瓷慢,且酸性的副產物有時會引起發炎反應。相對的,可生物降解的生物陶瓷材料在預期內有最快生長率,且其對光波與聲波在大腦中的應用具有診斷優勢。

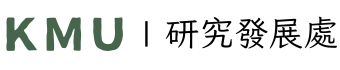

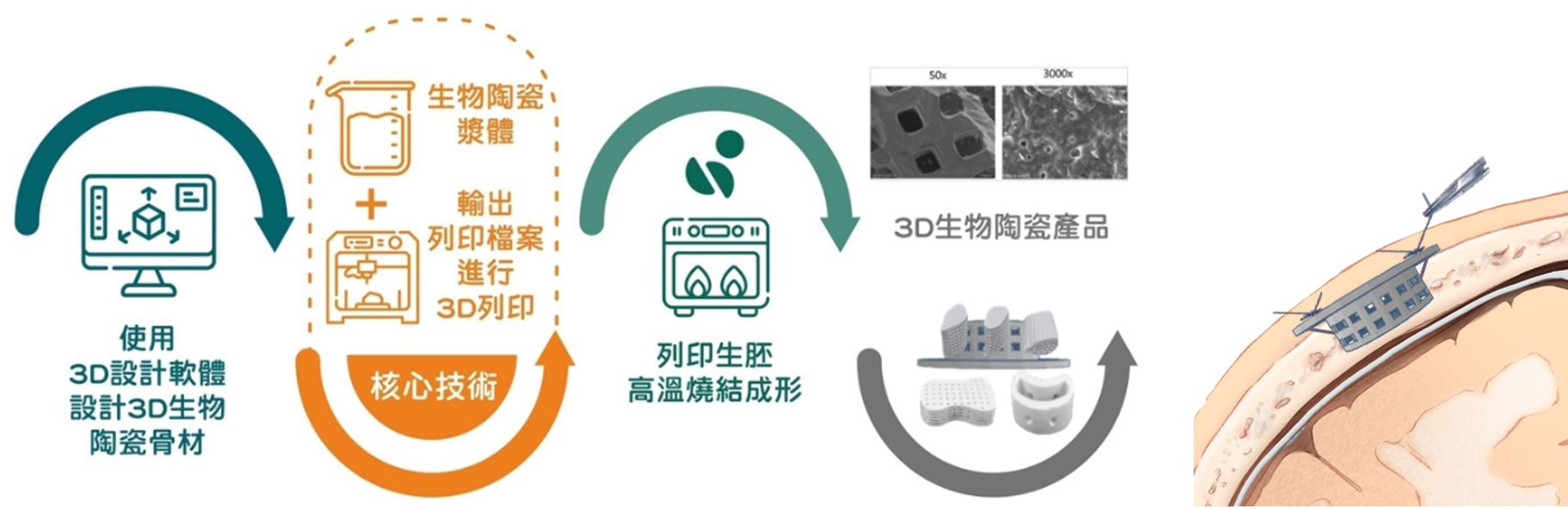

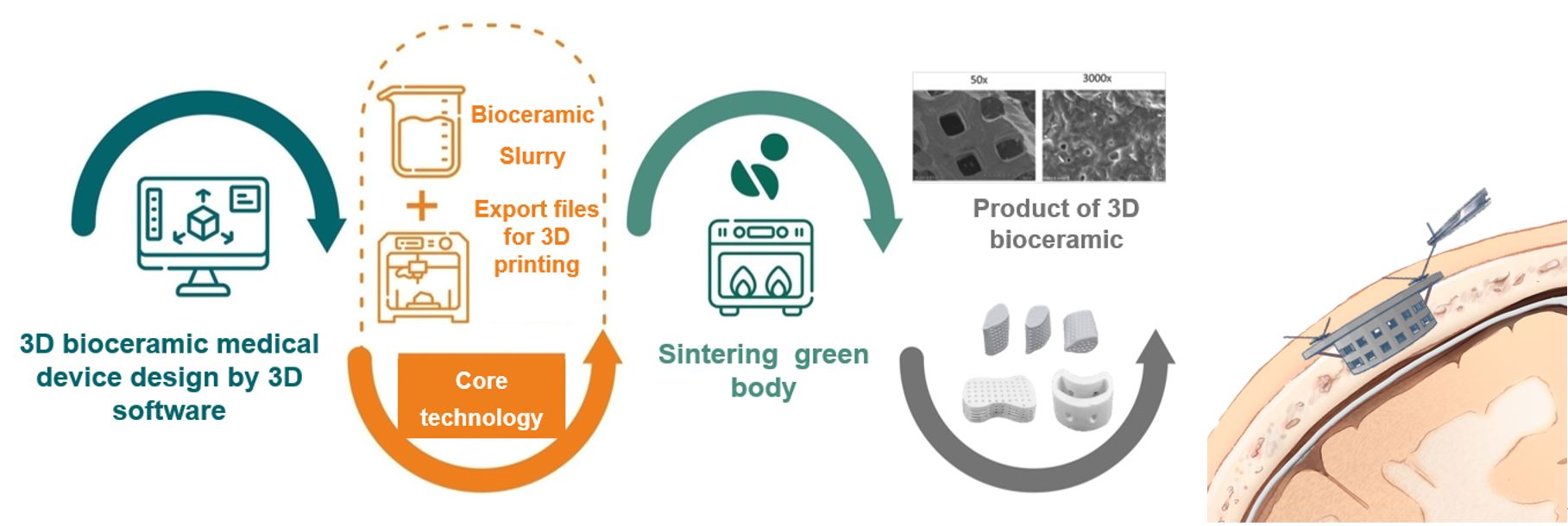

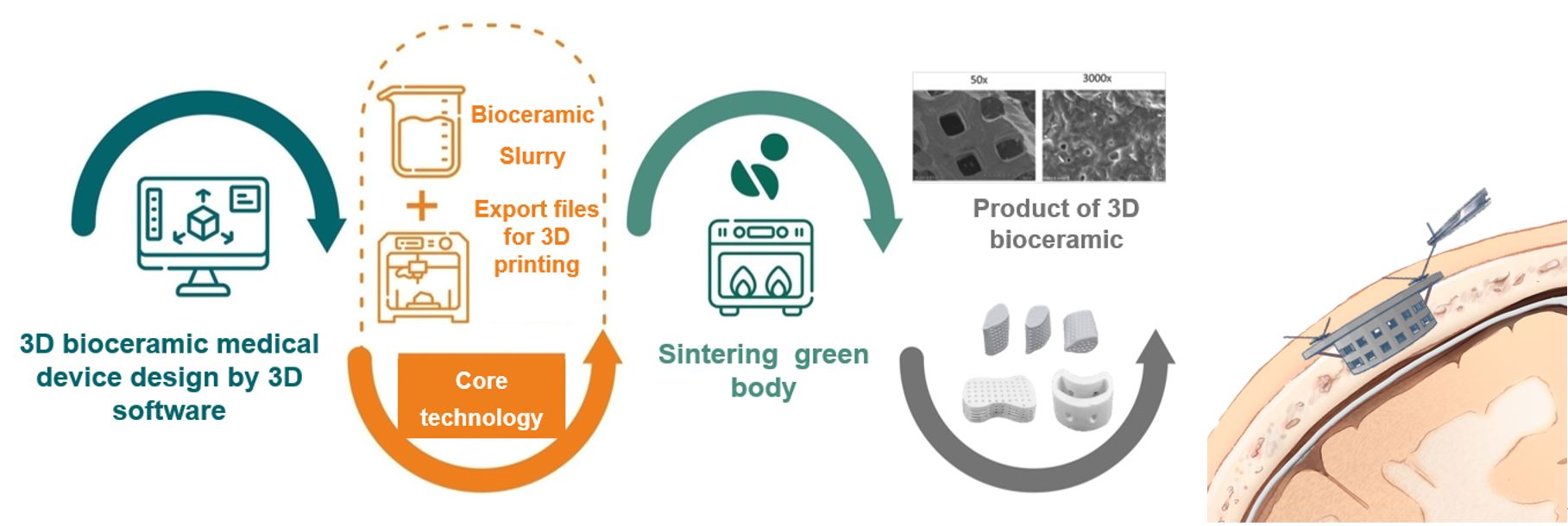

傳統多孔生物陶瓷骨移植替代物的機械性能和骨整合效率,無法彌補骨組織修復時需要的強度和適當生物降解率要求,因而限制了其臨床應用範圍。本團隊開發具光固化與負溫感雙功能性之專利陶瓷漿料系統,可於數位光投影(DLP)的積層製造機台,建立具有雙連續相之相互聯通孔洞結構與優異機械強度的3D生物陶瓷支架技術;即將生物陶瓷漿料光固化成3D精雕生坯體,於高溫燒結過程中,使得負溫感生物陶瓷生胚經過自我均勻收縮排液作用促進燒結緻密化增進機械性能。

圖形摘要

【應用與亮點】

本研究團隊致力於使骨移植替代物更準確、有效和安全。本技術使臨床醫生能夠提供精確且滿足患者需求的骨移植替代物,從而改善患者治療效果和手術效率。對於患者而說,可降低不良副作用的風險和提高治療性能,進而更快地恢復。

主要技術特點如下:

◆適當的機械特性

◆促進骨整合效率

◆良好的生物相容性

◆標準化與客製化

◆類似於常見的臨床材料成分

【研究團隊】

團隊成員:王志光教授、李之昀、王郁惠、齊俐安、王潔瑩

臨床顧問:陳崇桓醫師、蘇裕峯醫師、林松彥醫師

代表單位:再生醫學與細胞治療研究中心

團隊簡介:目前擁有三項佈局全球的負溫感陶瓷漿體的專利系統,致力發展「更快癒合、具支撐性3D生物陶瓷骨材」的積層製造技術,應用於個人化骨癒合的精準骨移植替代物,以促進人類健康福祉為首要任務。

研究聯繫Email:ckwang@kmu.edu.tw

Cranial burr hole cover of 3D bioceramic bone graft substitute using the additive manufacturing method

Cranial burr hole cover of 3D bioceramic bone graft substitute using the additive manufacturing method

"Chronic subdural hematoma" refers to the accumulation of hemorrhagic blood between the dura and the arachnoid. It is one of the common diseases in neurosurgery. A craniotomy is the preferred surgical method for clinical treatment of this disease. The materials used are divided into titanium metal, non-degradable polymers (PEEK, PMMA), biopolymers (PCL, PLA, etc.), and biodegradable ceramics. However, titanium metal has the problems of image interference and unfavorable phototherapy and ultrasound therapy for the brain, and non-degradable polymers (PEEK, PMMA) have the risk of inflammation and discomfort. Although biodegradable polymers such as PCL and PLA have osseointegration, their bone cell affinity and osseointegration rate are slower than those of bioceramics. Acidic by-products can sometimes cause inflammatory responses, while biodegradable bioceramic materials are expected to have the fastest growth rate over the forecast period and have diagnostic advantages for l phototherapy and ultrasound therapy for the brain.

The mechanical properties and osteointegration efficiency from traditional porous bioceramic bone substitutes cannot compensate for the strength and optimal biodegradation rate requirement for bone tissue repair, which limits its application. Our team developed the bifunctional ceramic slurry systems that comprise light-curing and reversible negative thermal-responsive. It is an important thing that can be build-up bicontinuous 3D bioceramic scaffold technology with interconnected channel structure and excellent mechanical strength object in the digital light projection (DLP) 3D printer. Whatever, the patented bioceramic slurry can be light-curing into a 3D precision sculpture green-body. And then, the component of the negative thermal-responsive green-body will undergo shrinkage and drainage to promote sintering and densification under the high-temperature sintering process. Finally, it can achieve well mechanical properties within the bicontinuous 3D bioceramic scaffold.

Graphical Abstract

Application and Highlights:

We are working to make bone replacements more accurate, effective, and safe. Our product allows clinicians to provide bone scaffolding that precisely matches patient needs and simplifies workflows, thereby improving patient outcomes and procedural efficiency. For patients this offers a lower risk of adverse side effects and optimal performance resulting in faster recovery.

The major technical features of our method are listed below:

◆Appropriate mechanical properties

◆Promote osteointegration efficiency

◆Well biocompatibility

◆Standardized and customized

◆Similar to clinical commercial mateial

Research Team Members: Prof. Chih-Kuang Wang, Chih-Yun Lee, Yu-Hui Wang, Li-Ann Chi, Jie-Ying Wang

Clinician Consultant: Dr. Chung-Hwan Chen、Dr. Yu-Feng Su、Dr. Sung-Yen Lin

Representative Department: Regenerative Medicine and Cell Therapy Research Center (RCC)

Introduction of Research Team: The team has three patents for negative temperature-sensitive bioceramics system that are deployed around the world. We have been committed to the development of " healing faster, and supportive 3D bioceramic aggregates" 3D printing technology. Precision bone graft substitutes for personalized bone healing with the primary mission of promoting human health and well-being.

Contact Email: ckwang@kmu.edu.tw